Seed Terminator: A Commitment to Quality – Sustainable Agriculture with Seed Terminator and Bisalloy Steels

In Australia’s rapidly evolving agricultural landscape, Seed Terminator has emerged as a global leader in mechanical weed control. Their innovative seed mill technology, designed to reduce reliance on chemical herbicides by crushing weed seeds during harvest, is transforming modern farming. Central to this breakthrough is the use of steel from Bisalloy Steels—Australia’s only manufacturer of high-tensile and abrasion-resistant quenched and tempered plate. Bisalloy’s Q&T steel provides the strength and durability required to withstand extreme agricultural demands, ensuring Seed Terminator’s mills are both resilient and efficient.

BISALLOY® Wear 500 Steel characteristics

Thickness

8-100mm

Brinell Hardness (Typical)

470-530 HB

Tensile Strength (Specification)

1640 MPa

Breaking the Cycle of Herbicide Reliance and Resistance in Agriculture

Dr. Nick Berry, Founder and Director of Research & Development at Seed Terminator, explains:

“Weed management has become one of the biggest challenges facing modern agriculture. Overreliance on chemical herbicides has led to the emergence of herbicide-resistant weeds, raising both costs and environmental concerns. The Seed Terminator intercepts weed seeds collected by the combine harvester, pulverising the weed-laden chaff component at harvest. This reduces the number of viable weed seeds returning to the soil, thereby helping to combat herbicide resistance.”

Bisalloy Steels – Quenched and Tempered for Strength and Durability

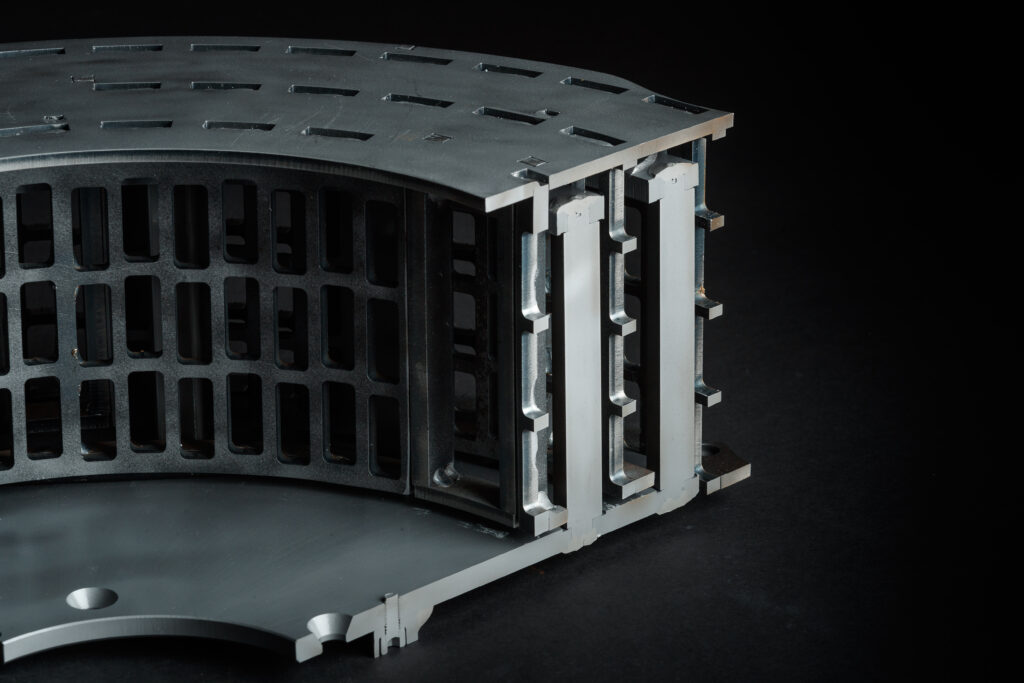

Bisalloy’s quenched and tempered (Q&T) steel offers a unique combination of strength and reduced weight, achieved through alloying elements such as chromium and molybdenum, along with a specialised heat treatment process. This allows Seed Terminator mills to operate around the clock in Harvest season and withstand the extreme conditions of Australian farming, where dust, dirt, and abrasive environments are constant. Compared to traditional mild steel, Bisalloy’s high-strength steel provides greater resistance to wear and tear while minimising the overall weight of the components. This balance of strength and reduced material thickness enhances the durability of the mill while also reducing the load on the combine during harvest.

Seed Terminator has incorporated BISALLOY® Steel into several different mill screen configurations, providing farmers with flexible options to suit their specific harvest conditions. These configurations allow farmers to select the best setup for their particular weed and crop scenarios, ensuring optimal performance across various conditions. The result is a proven eradication rate of 99% for Lolium rigidum (annual ryegrass), one of Australia’s toughest and most persistent weeds.

Dr. Berry emphasised the importance of selecting the right steel: “We chose BISALLOY® Wear 500 Steel for its superior erosion resistance, especially in the harsh, abrasive conditions of Australian farms. Aussie sand needs Aussie steel.”

“Seed Terminator’s focus on sustainability and performance aligns well with Bisalloy’s values. Our steel is engineered to perform in extreme conditions, making it an ideal choice for their mills.”

Simon Anderson, State Manager at Bisalloy Steel

Building Reliability with Bisalloy to Meet the Demands of Harvest Time

Upgrading to BIS500 in 2019 significantly improved the durability of Seed Terminator’s mills, ensuring they can withstand the tough conditions of Australian agriculture without requiring frequent part replacements. This has resulted in longer operational lifespans and minimal downtime during critical harvest periods.

Simon Anderson, State Manager at Bisalloy Steel, comments: “Seed Terminator’s focus on sustainability and performance aligns well with Bisalloy’s values. Our steel is engineered to perform in extreme conditions, making it an ideal choice for their mills.”

Greg Stevens, General Manager, Seed Terminator, further elaborates: “Farmers trust our equipment because they know it’s built to last. Thanks to Bisalloy’s steel, our mills are reliable, durable, and capable of withstanding the extreme conditions that farmers face, especially at critical harvest time.”

Simon Anderson at Bisalloy notes: “Every agricultural application presents unique challenges, and we’re continually adapting our steel to meet these demands.”

Farmers See Massive Reductions in Weed Persistence

For farmers, the benefits of Seed Terminator’s machinery are clear. Ongoing university trials in Australia and overseas show that the Seed Terminator can eradicate up to 99 percent of ryegrass seeds collected by the harvester. By destroying weed seeds during the harvesting process, farmers can reduce their reliance on chemical herbicides, leading to significant cost savings and more sustainable farming practices.

Kim Slarke, a farmer from Lake Grace, Western Australia, shares:

“All your ryegrass and weed seeds—get them threshed out, get them on your sieves, and get them through the Terminator. That’s the go.”

Sustaining Farms for Future Generations

Looking forward, both Seed Terminator and Bisalloy Steels are committed to pushing the boundaries of agricultural technology and materials. As farming practices evolve, so too must the technology and materials that support them. Seed Terminator is continually testing and improving its designs, and Bisalloy continues to provide the steel solutions necessary to meet future demands.

Dr. Berry concludes:

“As technology evolves, Seed Terminator is well-positioned to stay at the forefront of innovation. We’re delivering products that help farmers increase productivity while reducing their environmental impact. Delivering solutions that help them look after their land for the next generation.”

While Seed Terminator leads the charge in revolutionising agricultural machinery, Bisalloy’s steel provides the durability and strength required for these innovations to perform. Farmers are benefiting from more reliable, efficient, and sustainable weed control solutions, thanks to Seed Terminator’s integration of Bisalloy’s quenched and tempered steel.